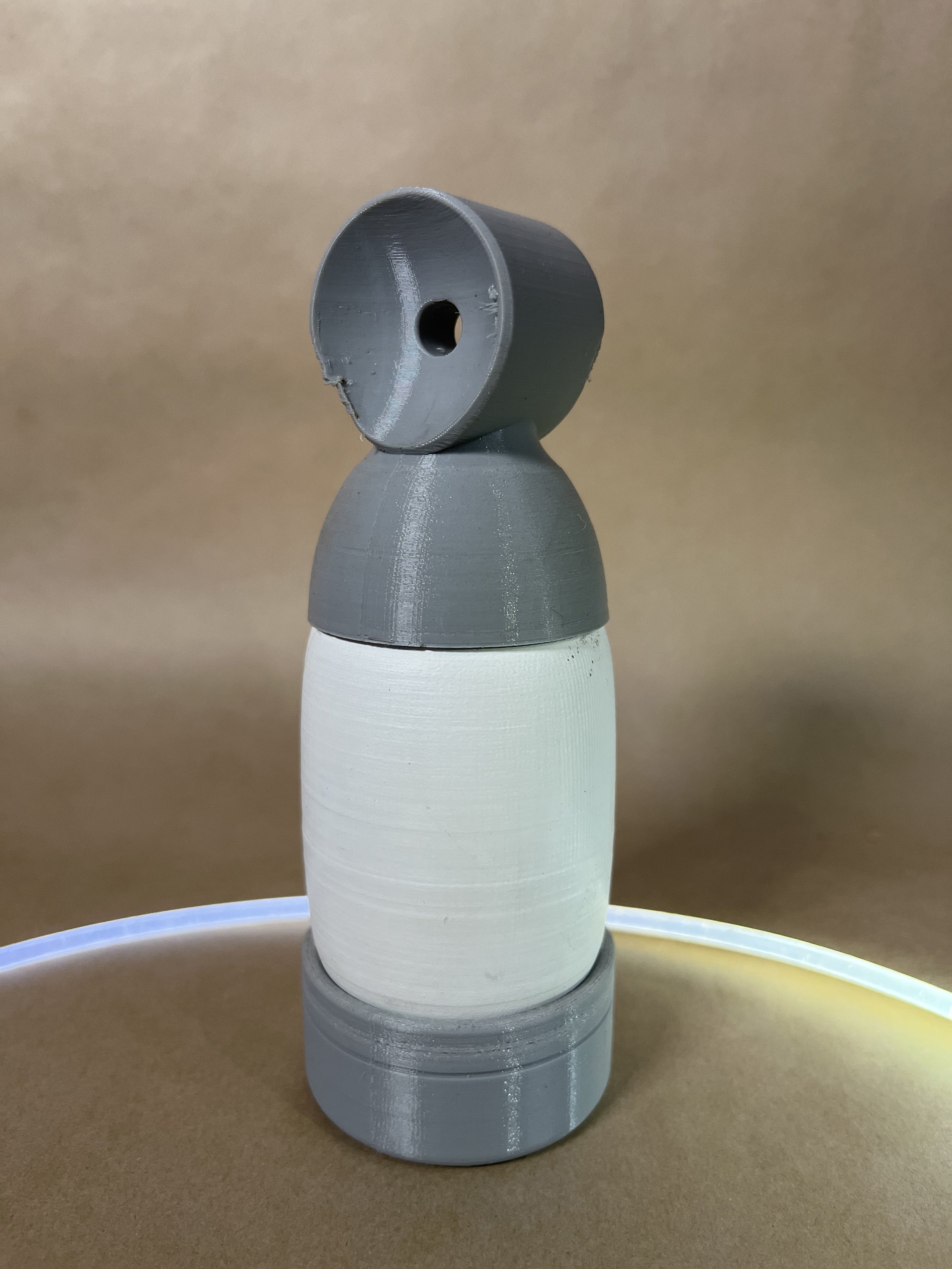

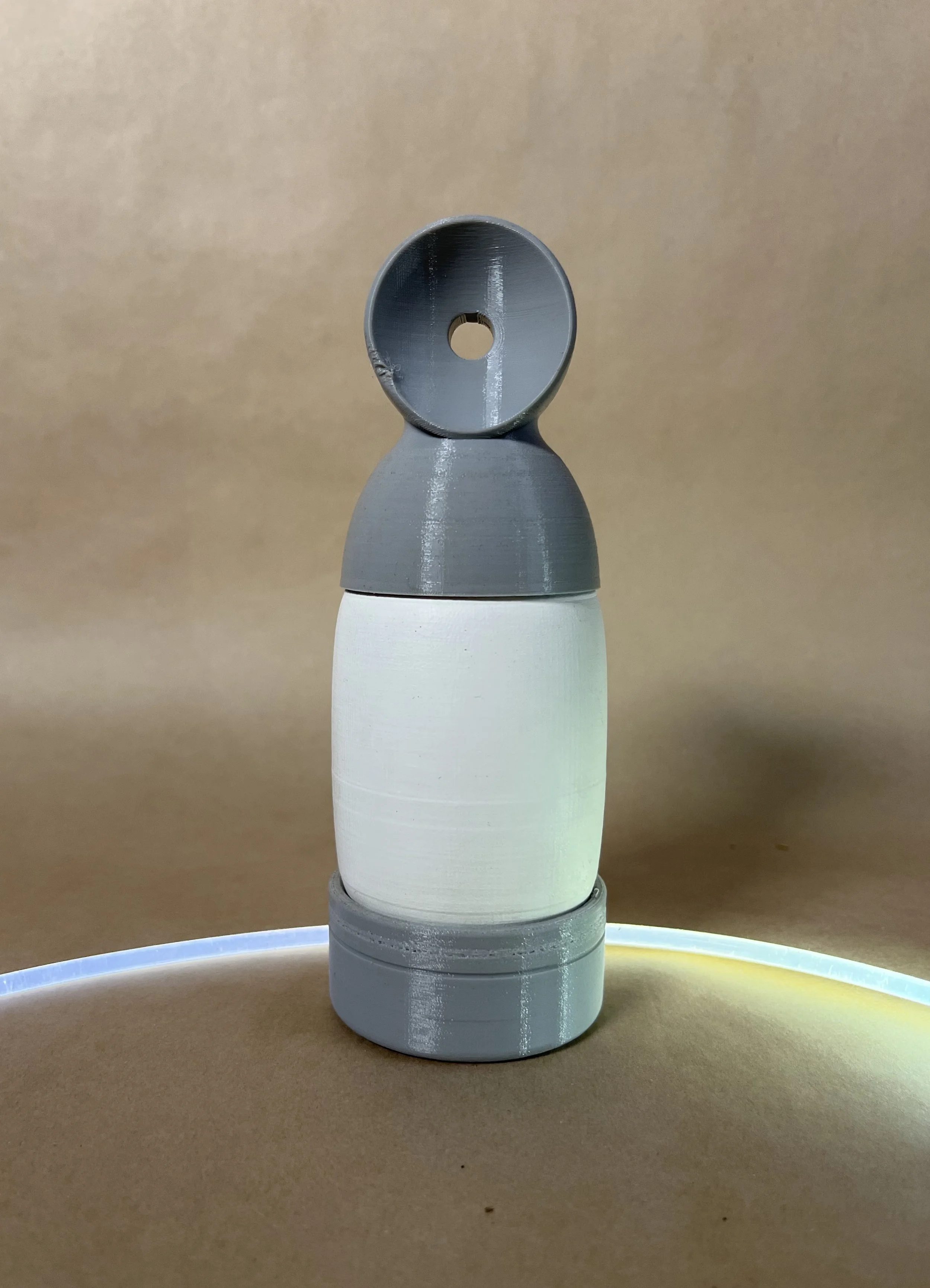

Rapid Prototyping

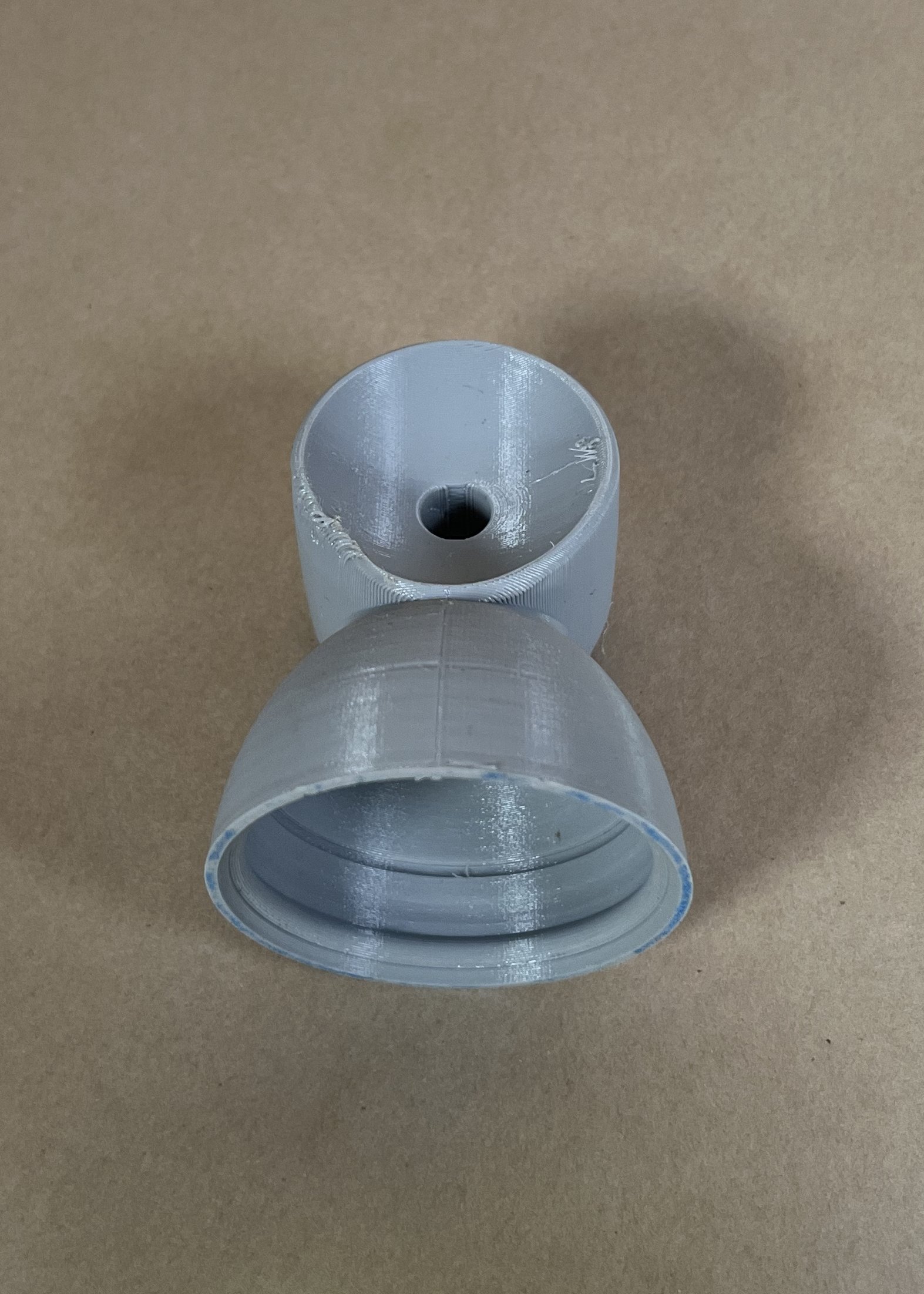

Developing the functional form for the nectar distribution container has been an iterative process using CAD software and a low-cost 3D printer. We’ve experimented with various materials and forms to ensure a modular and reusable component design. Now that the functional/interlocking elements are complete we can focus on material and aesthetic improvements to the container.

Learnings

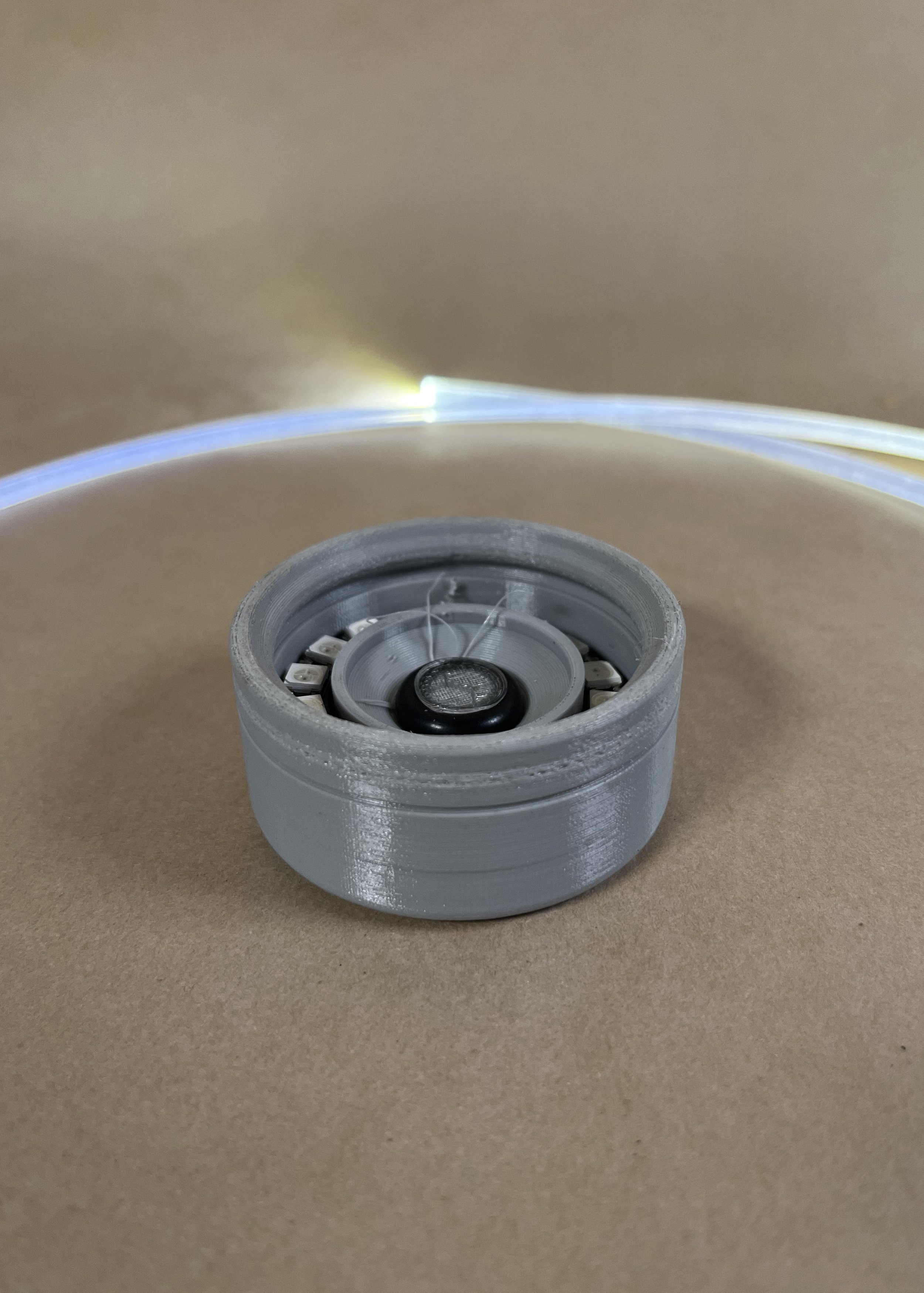

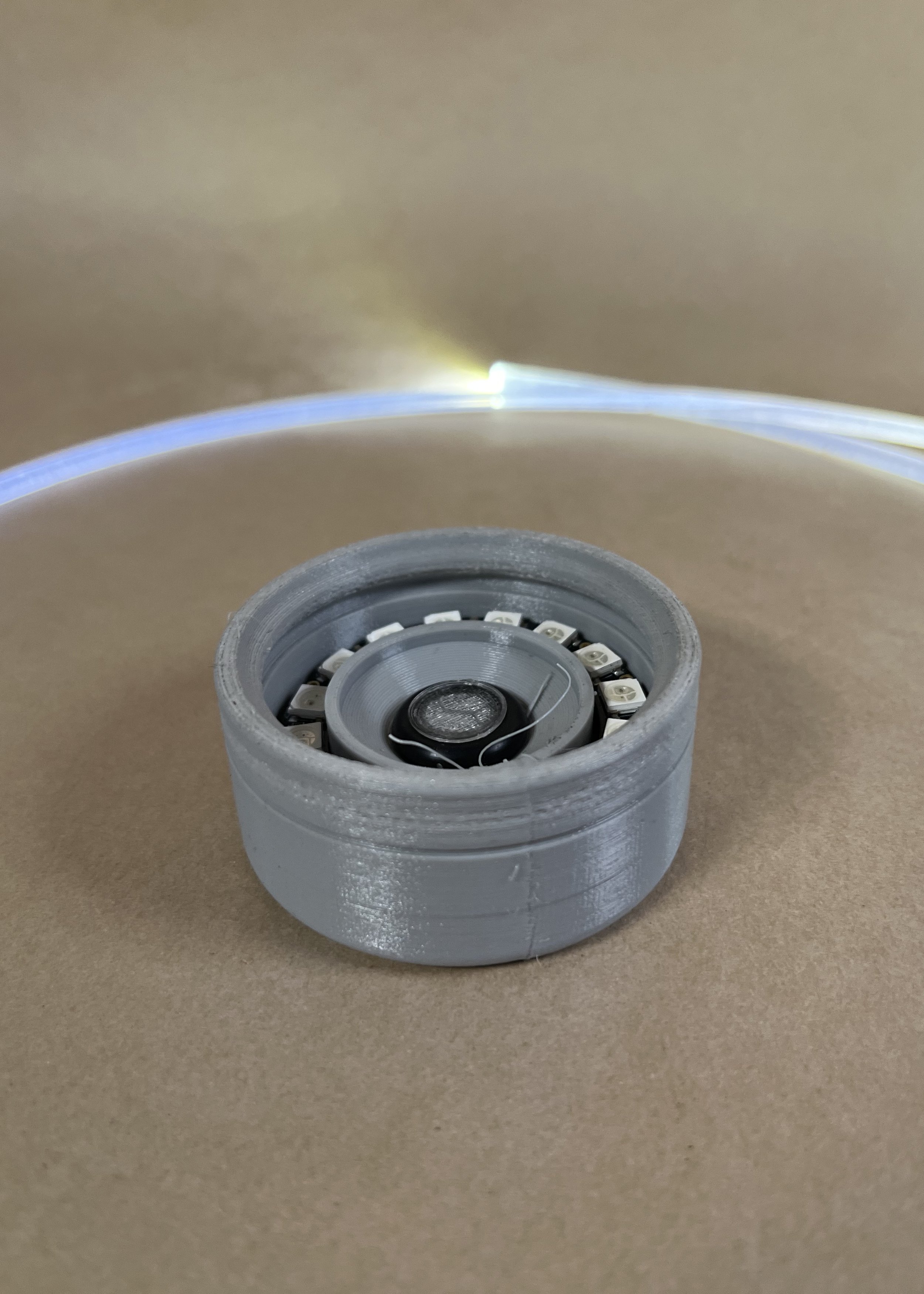

An 85 Shore hardness material for the top and base provides enough flexibility to interlock with the main body while remaining rigid enough to fulfill the structural requirements of the form.

A series of ridges at the top and bottom of the body creates a strong lock that requires a twisting motion to release.

An additional O-ring between the body and base is required to complete the seal and prevent liquid from reaching the electronic components.